Commercial kitchens must maintain correct food temperatures without compromise. As the statistics show, improper temperatures directly translate to food safety hazards and lost revenue through wasted products and customer dissatisfaction.

The Growing Threat of Foodborne Illnesses

Annual foodborne illness outbreaks are on the rise. According to the CDC, contamination-related diseases lead to over 128,000 hospitalizations and 3,000 deaths annually. As the FDA notes, improper food temperatures play a significant role, contributing to 48 million cases per year.

Custom flexible heaters enable restaurants to precisely control cooking temperatures, preventing undercooking and bacterial growth. Carefully controlled heating processes enabled by the bendable pads reduce safety risks.

Common Causes

Germs and parasites from unsafe food cause around 250 different foodborne diseases. Salmonella, listeria, and E. coli are some examples. Undercooking, improper holding temperatures, and poor hygiene during prep typically enable contamination.

Utilizing the best flexible custom heaters, commercial kitchens can maintain foods at optimal serving temperatures for extended periods without risking drying or burning. This prevents bacteria from regrowing after initial prep.

High-Risk Foods

Meat, dairy, eggs, and seafood are frequently implicated items. Produce like lettuce and fruits also pose challenges. Improper prep or storage at the wrong temperature gives pathogens room to multiply on highly nutritious foods.

With built-in sensors, custom flexible heaters can monitor temperatures during key processes in real time. Automated controls quickly adjust pads to maintain meticulous heating protocols.

Consumer Demand for Proper Food Temperatures

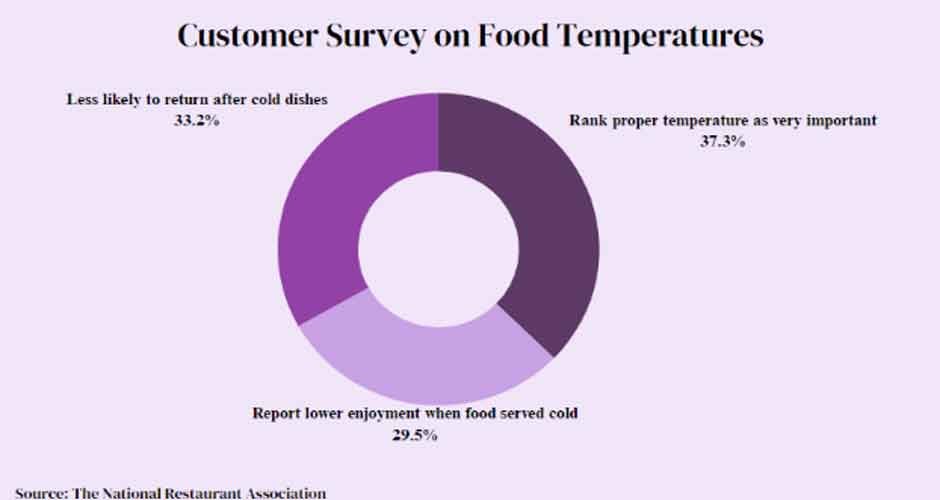

Inside the kitchen is one thing, but on the plate is what matters. An overwhelming 82% of customers rank food temperature as central to their dining experience satisfaction, according to the National Restaurant Association. Look at the data below that shows the customer survey on food temperature:

When the temperature is incorrectly managed, plates go cold before consumers have finished meals. This directly reduces enjoyment and loyalty scores.

The Commercial Solution: Heated Display Cases

Heated display cases are specially made cabinets that keep pre-made food at the right temperature for serving for a long time. They have heating elements built into them that keep all the food inside hot enough to eat for hours without drying out or burning the food touching the sides.

Global demand for these helpful display cases keeps going up. One research company predicts the market for these units will grow by 4.3% per year between 2021-2028.

Heated display cases work by using heating elements that warm the air inside the cabinets. Fans circulate this heated air so it reaches all the food, keeping everything at a safe temperature. Controls let staff set the right temperature for different foods from hot soups to warm desserts.

Doors on the front keep the hot air inside. This lets employees grab food quickly when needed while preventing cold drafts that would cool everything down. Some models have night curtains that provide extra insulation when closed.

Additionally, many heated display cases come equipped with built-in humidifiers. Adding some moisture to the heated air helps lock in flavor and prevent foods from drying out under the warming lights. The humidity level can be adjusted to be higher for moist foods like freshly baked bread or lower for crisp items like fries.

Heated display cabinets come in different sizes and designs. Smaller countertop units can hold food for a few hours for small restaurants. Giant floor models for catering keep mountains of food piping hot for banquets and buffets. Custom options like all-glass doors or wooden finishes allow matching display cases to a restaurant’s decor.

Enhancing food safety constitutes a primary benefit; however, proper food handling also results in reduced waste. Restaurants can prepare more dishes ahead of rush periods without worrying about food deteriorating. Grocery stores have a longer shelf life for hot, prepared meals and baked goods. Fewer throwaways mean higher profits.

Harnessing Flexible Heater Technology

While heated cabinets maintain temperatures post-cooking, achieving precise temperatures during food preparation falls to flexible heaters. These thin, bendable heating elements can wrap around any object.

Some key benefits include:

- Energy Efficient: Flexible heaters use over 90% of energy for heating, reducing power use by 30%

- Even Heat Distribution: Because they are very thin, they can wrap around complex shapes with no hot or cold spots

- Safe: Low heating temperature prevent burns

- Adaptable: Can be equipped with automatic temperature controls and sensors for precision

Leveraging both heated cabinets and flexible heaters enables commercial kitchens to ensure food safety, enhance taste, and boost profits.

Some restaurants that adopted this technology increased food temperatures by 20%, reduced food drying by 30%, improved customer meal enjoyment scores by 18%, and experienced a 15% boost in sales.

A grocery store reduced food waste by over 35% because fruits and vegetables stayed fresher longer, thanks to properly heated produce displays. For one store tested, this equaled getting back over $500,000 in revenue from less wasted fresh food.

A catering company that used flexible heaters to keep food hot inside warming bags reduced customer complaints about cold food by 55% compared to just wrapping plates in blankets. They also spent 40% less on throwing away unsold prepared food.

Real-world Examples of Temperature Optimization

Deploying heated cabinets and flexible heaters enables commercial kitchens to achieve food safety compliance while improving quality and profits.

Restaurants that implemented this technology increased food temperatures by 20%, reduced drying by 30%, boosted meal enjoyment scores by 18%, and realized 15% sales gains.

Grocery retailers cut throwaways by over 35% by prolonging produce shelf life via properly heated displays. This translated to over $500,000 in recovered revenue for a pilot store.

Catering companies using flexible heaters inside warming bags decreased customer temperature complaints by 55% compared to blanket-wrapping plates alone. They also trimmed waste spending by 40% as less prepared food was discarded.

FAQs

How do heated display cases retain moisture and texture?

Built-in humidity controls regulate moisture evaporation, ensuring that foods do not dry out under the heating elements. Strategically positioned vents also promote air circulation for even warming distribution.

Are flexible heaters more energy-efficient than conventional ovens?

Yes, flexible heaters offer over 90% energy conversion efficiency, compared to 70% or less for standard ovens. Their ultra-thin design also enables precision heating without wider temperature fluctuations, leading to heat waste.

Can heated cabinets and flexible heaters be tailored to specific menu items?

Certainly, modern heated displays and flex heater systems feature adjustable shelve heights, unique heating zones, and customizable programming options to cater to the precise holding needs of individual dishes.

Conclusion: Embrace Advanced Heating Technologies

Adhering to strict food temperature protocols is essential in today’s high-risk environment. Heated holding cabinets and flexible heating systems deliver the safety, quality, and profit improvements that commercial kitchens demand.

As the research and real-world cases prove, these technologies provide unmatched temperature precision, moisture retention, and energy efficiency compared to conventional ovens and open displays.

By investing in upgrading heating and holding infrastructure, food service businesses can enhance food safety, customer satisfaction, and the bottom line simultaneously. The solution is clear – embrace innovation to optimize food temperature management now.

Comments