An effective work environment is built on well-organized tools, yet it’s easy to make the same errors again and over again. This thorough article will cover five common mistakes you should never make when arranging your equipment so your workstation stays productive and organized. Preventing accidents is preferable to facing the repercussions later on.

1. Neglecting Categorization: The Pitfall of Unsystematic Arrangement

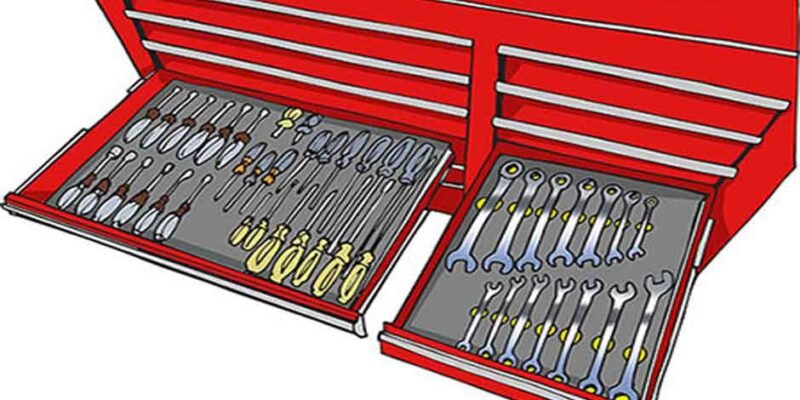

Ignoring classification is one of the most frequent errors in tool organization. When tools are placed together randomly with no clear order, it takes longer to find what you’re looking for. Sorting your tools by kind or usefulness is essential, and you should designate distinct sections or containers for each category. Think about the mayhem that results from mixing different tools, no matter what they are meant for. Frustration and inefficiency result from the mixing of screws and wrenches and the tangling of measuring tapes with pliers. Adopt a systematic strategy by allocating specific areas for groups, such as power tools, measurement tools, or cutting tools.

2. Overlooking Tool Maintenance: A Recipe for Decline in Efficiency

Neglecting tool upkeep is a part of tool organization that is often overlooked. As important as it is to consider where to keep your instruments, you risk losing productivity if you don’t take proper care of them. To guarantee that your tools are always in top operating order and available for use when required, do routine maintenance and inspections. Imagine the following situation: you reach for a tool, and it’s broken, corrupted, or not working properly. This error not only throws off your workflow but also lowers the quality of your output. Establish a regular maintenance regimen that includes sharpening blades, lubricating moving components, and looking for wear indicators.

3. Disregarding Safety Measures: A Risk to Your Well-Being

Disregarding safety precautions is one component of tool organization that is often neglected. Inappropriately putting heavy or sharp instruments puts your safety in danger, in addition to endangering the equipment. Avoid making the error of setting up your workstation without taking safety into account. Imagine opening a toolbox without taking the necessary safety measures and discovering exposed blades or unstable, weighty things. Investing in a truck tool box organizer can also play a crucial role in maintaining a safe and organized workspace, ensuring that your tools are stored securely and minimizing the risk of accidents. Adopt safety precautions, including locking heavier things at the bottom of your toolbox, sheathing sharp objects, and arranging potentially dangerous instruments to reduce the chance of unintentional contact.

4. Underestimating Storage Needs: The Pitfall of Limited Space

When organizing tools, underestimating storage demands is a typical error. If you don’t plan for the expansion of your tool collection, your workstation can become disorganized and ineffective. Setting aside enough room and making plans for future growth are crucial in order to make room for more tools or equipment. When you buy new equipment for specific jobs, imagine how frustrating it is to have restricted storage. Your productivity can suffer if your tools wind up scattered all over your desk due to a lack of space. Choose tool storage options that are expandable, such as toolbox drawer extensions or modular shelves.

5. Disorganization in Portable Tool Boxes: A Common Oversight

Though disarray within these little containers is a regular error, portable toolboxes are a practical alternative for those who are always on the go. Because of its small size, a portable toolbox has to be carefully planned so that every item is placed effectively and is accessible when needed. During work, when time is of the essence, picture the aggravation of having to search through a disorganized portable toolbox to locate the correct screwdriver. Use organizers, dividers, and segmented trays found in portable tool cases to take advantage of this design flaw and prevent it. Make sure that every tool has a place of its own so that there isn’t a disorganized mess that slows down retrieval.

Conclusion

Effective tool organization is a craft that calls for accuracy, vision, and a dedication to upkeep and safety. You can take your workplace to a new level of productivity and efficiency by avoiding typical blunders like underestimating storage requirements, ignoring tool upkeep, categorizing poorly, and letting disarray take over in portable tool boxes. Adopt a systematic and strategic approach to organizing your tools so that they serve to enhance and improve productivity in addition to having a specific location.

Comments