The last century has seen the automotive industry undergo remarkable change. But one manufacturing process has never lost its importance. Sheet metal fabrication is the backbone of all the machine work concerning the construction of cars. It accounts for nearly all of the visible and structural components of a car. The technique covers car body panels, parts of the chassis, brackets for the interior, engine components, and a whole lot more. It takes flat sheets of metal and forms them into complex three dimensional parts of a car that covers both the design and the working functionality of the automotive industry.

The combination of sheet metal fabrication and CNC machining technology provides a window into the modern car manufacturing process. These are the basic processes that one has to know for automotive engineering, manufacturing, or even industrial designing. It is one of the most essential and universally applicable techniques in the industry and knowing it is important.

What Sheet Metal Fabrication Actually Involves in Automotive Production

Sheet metal fabrication involves several procedures through which flat metal sheets undergo multiple operations of cutting, bending, forming, and joining to produce finished components. The metals used in automotive applications are normally differentiated as steel, aluminum, or certain alloys depending on performance features such as strength, resistance to corrosion, and lightweight construction. Certain alloys are used for specific applications depending on the automotive industry’s needs.

Automotive manufacturers choose the materials and gauges as per the intended function and performance of the components. Performance requirements determine the thickness of gauges. Differences of sheet metal fabrication from other types of manufacturing such as casting or forging are significant! While casting involves pouring molten metal into molds or forging where solid billets hammered into the desired shape, sheet metal fabrication involves mechanical procedures to pre-formed sheets. This results in the efficient use of materials, and flexible designs, and the ability to produce large and complex shapes at lower costs.

CNC machining technology has changed how sheet metal fabrication works over the past few decades. Computer Numerical Control systems automate the cutting, punching, bending, and forming making it impossible for manual methods to compete. The National Institute of Standards and Technology states that current CNC fabrication systems offer accuracy within 0.01 millimeters and do the job at speeds incomparable to manual processes.

Primary Sheet Metal Fabrication Processes Used in Automobile Manufacturing

The car industry uses various methods to make different sheet metal components. Learning about these methods helps to understand how different parts of a car are made.

The first steps of any sheet metal fabrication is blanking and cutting. Flat patterns are cut from sheet metal and these patterns are made into components. From these components, more complicated parts can be made. For complicated parts, laser cutting is preferred but for simple parts, punching is more efficient because it is faster.

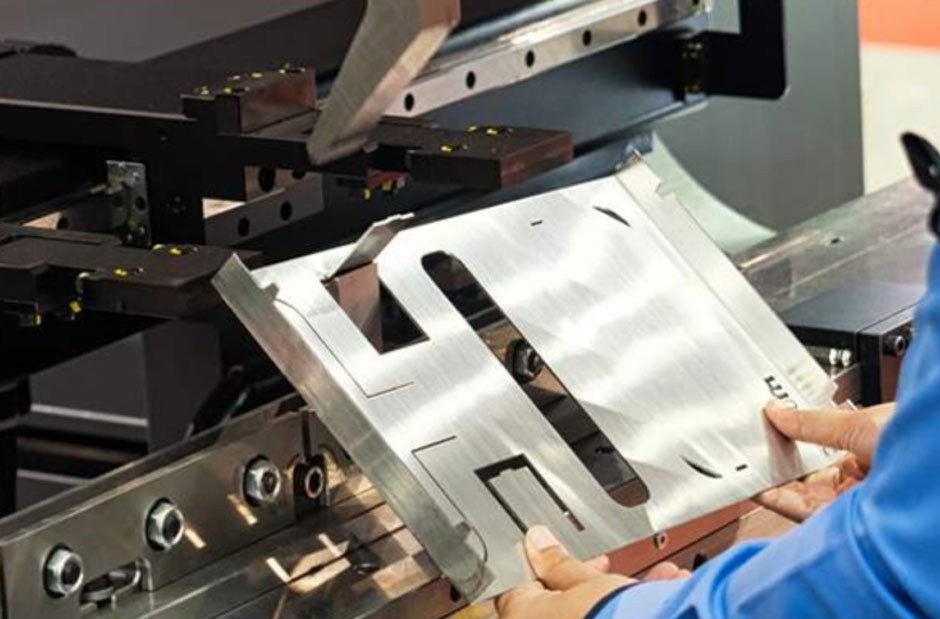

The next steps are bending and forming and these steps are used to make 3D components from 2D shapes. To create angles and curves on a 2D shape, CNC press brakes can be used. For more advanced shapes, specially designed hydraulic or mechanical presses can be used which shape the 3D form from a flat sheet. Body panels also have a 3D form and can be made with a deep drawing process.

In the stamping process, cutting and forming are combined into one process. This process works on a large scale, making it efficient for the production of internal parts which are made in millions. Automotive stamping can make parts from heavy steel and uses a lot of force.

Hydroforming shapes metal sheets using fluid presure. It allows the flushing of tight spaces and preventing unsightly and damaging wrinkles and tears. Cross members and frame section produced through this process create structural components which optimize both strength and weight. The process achieves these results through equal pressure distribution which achieves shapes hard and impossible to get using standard metal stamping techniques.

Assemblies create larger bodies of work using multiple fabricated components. Spot welding dressed the body and integrated structural components using hundreds of welds placed in specific positions. Heavily integrated structural components receive laser welding to fuse seams and provide clean joints. Bonding adhesives take the place of and accompany metal filler welding in joints made of aluminum and advanced high-strength steels.

Critical Automotive Components Created Through Sheet Metal Fabrication

Modern cars can have hundreds of sheet metal, fabricated components produced through CNC-controlled processes. Looking closely at specific instances can show just how flexible and valuable this technology can be.

Most of these cars have body panels which consist of fenders, doors, and roofs. These designed fabricated components also provide trunk lids and protective covers. While these panels offer shelter and protection, they also define a car’s shape and style. The surface of these panels goes through very detailed and advanced forming processes, creating compound curves and character lines for the forming processes. These sheet metal components also need a high quality surface. Any minimum scratch or cavity will be evident post painting, so they need to be smooth.

The rest of the components make up the “skeleton” of the car and provide structural support. These components provide structural safety and also attach parts of the car. Like the structural skeleton, rocker panels, floor pans and cross members also need to be fabricated into intricate shapes. Modern cars now use advanced high-strength steel for these parts, so the equipment and techniques for the sheet metal need to be more advanced also.

The car’s chassis also has frame components which consist of heavy gauge sheet metal. These parts consist of channel and box sections and more complex sheet metal brackets. These parts need to create crush zones for cars so they need to withstand heavy loads. These parts also provide impact energy absorption during collision or crash and the rest of the panels need to provide structural support.

Oil pans, valve covers, transmission cases, and heat shields are made from sheet metal. These parts often have complex shapes that include mounting bosses, cooling fins, and sealing surfaces. After forming, parts are frequently CNC machined to create mounting holes and surfaces that will mate with other parts.

Interior parts including seat frames, dashboard supports, door inner panels, and various brackets in the cabin are made using sheet metal fabrication. Parts must create enough structural strength while considering weight and accommodate mounting points for trim, electronics, and safety equipment.

For the exhaust system, sheet metal is first formed to make the manifolds, catalytic converter housings, muffler shells, and tailpipes. These parts are exposed to high temperatures and need to maintain their shape while sealing in exhaust gases.

How CNC Technology Enhances Sheet Metal Fabrication Precision

Incorporating Computer Numerical Control technology has changed the way sheet metal fabrication is done the process is now mostly automated and done with precision. This has been especially important in the automotive industry where production has to be consistent, fast, and accurate.

CNC laser cutting systems are big advancements in fabrication technology. These machines focus high-powered laser rays and, with the help of computers, cut metal along designed paths. Today’s new technology cuts thin sheets of steel quickly and at 25mm thickness, it cuts also at high speeds. The edges don’t need touching up.

Laser cutting takes the CAD files with direction cutting sheets and defines the geometric parts. Also, nesting software is used to fit parts on the sheets in a way that reduces waste and exceeds 90% material utilization. The CNC controls the position to where the laser head will focus with extreme precision, with the programmed path making real time adjustments on material thickness and gas.

CNC punch presses are fast for making simple parts with a lot of holes in them. These machines have tool libraries with dozens of different shapes and sizes. The computer control system places the sheet metal in front of the right tools and punches hundreds of features in just a minute. Unlike traditional punching systems, modern servo systems offer similar flexibility to lasers while retaining speed punching.

CNC press brakes automate the bending process with the use of programmable back gauges, ram positioning, and tool selection. Operators just load the flat blanks and the machine runs the designated bending sequence with precision. With the system in place, the angle measuring system provides feedback which adjusts the ram’s position to target bend angles and compensate for material thickness.

Modern press brakes have fully automated systems drastically reducing setup time and giving no space for human error. These systems automate complex parts of production which have several bend radii or angles.

With robotic integration, the CNC systems now handle material prep, welding, and finishing. These systems load and unload machines, and control the production process which includes spot welding and adhesive application. The system works with high precision to guarantee quality and allows for production to run non-stop for 24 hours.

Material Selection in Automotive Sheet Metal Fabrication

The choice of metal alloy significantly impacts component performance, manufacturing processes, and vehicle characteristics. Automotive engineers select materials balancing strength, weight, cost, formability, and corrosion resistance.

Mild steel remains the most common automotive sheet metal material due to its combination of adequate strength, excellent formability, and low cost. Body panels, floor sections, and many structural components use mild steel gauges ranging from 0.6 to 2.0 millimeters thick. The material bends, forms, and welds easily using standard equipment and techniques.

Advanced high-strength steels provide exceptional strength-to-weight ratios, enabling thinner gauges that reduce weight while maintaining or improving crashworthiness. These materials include dual-phase steels, transformation-induced plasticity steels, and martensitic grades. However, their higher strength makes forming more challenging, requiring more powerful equipment and sometimes hot forming processes.

Aluminum alloys deliver weight savings of 30-50% compared to equivalent steel components. Automakers increasingly use aluminum for hoods, trunk lids, doors, and in some vehicles, entire body structures. Aluminum’s lower density and higher formability in certain alloys offset its higher material cost for weight-sensitive applications. However, it requires different welding techniques and poses galvanic corrosion concerns when joined to steel.

Stainless steel finds limited automotive use in exhaust systems and trim elements where corrosion resistance justifies its higher cost. The material’s hardness and work-hardening characteristics make fabrication more demanding than mild steel.

Different metal alloys result in different component performances along with different effects on the vehicle. When it comes to alloys, automotive engineers need to figure out the best combination of strength, weight, cost, workability, resistance to corrosion, and all the other factors associated with it.

Mild steel is the most common automotive sheet metal material because it also has an adequate combination of strength of formability along with a low cost supply. Body panels, floor sections, and a lot of different structural components use mild steel that is 0.6 to 2.0 millimeters thick. Mild steel is also easy to bend, form, and weld with standard tools and techniques.

Advanced high strength steel includes dual-phase steels and transformation induced plasticity steels.weigh Steele s in the range of 0.8 to 2 mm also The weight and strength ration is amazing because you can use thinner steel and get the weight down while still maintaining the strength and crashworthiness of the vehicle. The stronger the steel the tougher you have to gear up in order to form metal. Higher and sometimes hot form.

Compared to steel components, aluminum alloy losses weight of 30-50%. More and more aluminum is used on the hoods, trunk lids and doors and in some case, the entire bodies of the ‘body structre vehicles. Aluminum also has a lower density and a higher formability which can help in weight saving and cost sensitive projects; though different alloys can balance out aluminum’s higher cost in weight saving sensitive ang applications. Aluminum also galvanic corlose with steel so it is more troublesome to weld.

Stainless steel has limited use in cars, primarily in exhaust systems and some finishing elements, where the cost is worth paying for the resistance to rust. The material is harder and has work hardening properties making it more difficult to fabricate than mild steel.

Quality Control in Automotive Sheet Metal Fabrication

Automakers have and follow very stringent standards regarding the quality of their products during the procedures of sheet metal fabrication. Components have to satisfy the dimensional, visual, and functional criteria and undergo many inspection procedures before assembly.

Quality assessment of sheet metal starts with checking alloy composition, thickness, surface finish, and other mechanical properties. Supplier certifications said to have passed sample analyses and tensile tests. Surface inspections identify scratches, dents, and other defects or coatings that may affect the parts.

Inspections that occur during fabrication processes try to find issues before a large quantity of bad parts are created. At regular intervals, operators measure sample parts. Dimensional comparisons to engineering specifications are done. Methods of statistical process control measure and track process control to prevent drifting out of specified tolerances.

Coordinate measuring machines verify formed panels and other complex shapes against CAD models. In minutes, these systems measure hundreds of points to a component and create deviation reports. Parts that are out of tolerance are reworked or written off completely.

Distinct gaps exist to gray out high volume components and other body panels against customized or enhanced versions of automated systems. Automated systems that enhance instead of replacing human operators work to gain more reliability, particularly regarding high volume sections.

Functional testing checks whether the built assemblies work properly. This could include checking how doors fit and operate, verifying whether the crush zones properly deform on simulated crashed, or checking whether the exhaust components seal properly when pressure testing.

Real-World Applications and Industry Examples

Understanding a few cases of sheet metal processing in the automotive industry helps clarify the abstract principles of processing in the automotive industry.

An American truck manufacturer redesigned the truck bed using advanced high strength, steel sheet metal fabrication techniques. This design saved an impressive 60 kilograms, increasing the truck bed’s load capacity and making it resistant to scratches. Tie-down and light cutouts were intricately designed using CNC laser cutting, and the truck bed was constructed by robotic welding from numerous stamped pieces. It was a more efficient design that achieved an impressive lightweight and strength to the truck bed.

A European luxury sedan automaker used aluminum sheet metal fabrication for the car body. It also required the development of new CNC stamping dies, new adjustments to the dies, and new methods of fastening which incorporated spot welding, riveting, and gluing to the sheets. With this complexity, the aluminum structure also achieved an incredible reduction of 200 kilograms while maintaining all standards for crash safety.

An electric vehicle startup employed creative methods for making battery pack enclosure designs using sheet metal fabrication. Battery pack enclosures using aluminum sheets were constructed using CNC laser cutting. Integrated cooling channels were stamped and welded to housings for encapsulation and thermal management. The approach to fabrication showcased affordability to produce economically during development and design by realized low volume compared to volume pressures of conventional automakers.

Environmental Considerations in Automotive Sheet Metal Fabrication

How car makers think about sheet metal fabrication is changing because of sustainability. These processes have different sustainability challenges.

How much material is used will determine how much is wasted. Thankfully, new CNC nesting software helps place parts in such a way that no unused material is left. Any remaining unused material, or scrap, is recycled along with steel or aluminum. This recycling creates a closed-loop material system. Some facilities have scrap rates of under 10%. This means that over 90% of the sheet metal that these facilities take in is converted into finished components.

Different fabrication processes offer different amounts of energy consumption. For example, laser cutting uses a lot of electricity, but it eliminates the need for secondary finishing processes. In contrast, stamping uses a lot of energy but finishes the part in one operation. This means that the stamping machine will finish some parts in one step rather than go through a sequence. The laser cutter and stamping machine use different methods and have different energy consumption rates. This is one of the many factors that manufacturers will account for energy in the entire sequence of production.

Finishing and coating processes raise sustainability concerns particularly due to the waste and volatile organic compounds they emit. The problem is of primary concern in water-based coatings, powder coating systems, and advanced application methods that reduce waste. Integrated waste treatments that capture and neutralize waste will eliminate pollutants before they are released into the environment.

The advantages of using metal sheets for lightweight construction for vehicles last for the entire life of the vehicles. For every 100 kgs of weight a vehicle loses helps the vehicle get more miles to a fuel liter (0.3 to 0.4 liters per 100 kilometers). In a vehicles lifetime of 200,000 kilometers that is a staggering amount of fuel savings and a few tons of carbon savings. This carbon savings also exceeds the environmental cost of vehicle fabrcation.

Future Trends in Automotive Sheet Metal Fabrication

Sheet metal fabrication is an ever-evolving process as marked by the demands for lighter vehicles and new materials and for improved manufacturing efficiency. Some new trends are changing how automotive components are fabricated.

Additive manufacturing combines 3D printing and other fabrication techniques. Some manufacturers print complex brackets and reinforcements and directly attach them to formed sheet metal panels. This creates hybrid components that are impossible to build using only traditional methods. This method helps in optimizing the design for mass customization and sheet metal fabrication. This is another example of the cost and strength advantages of sheet metal.

Machine learning is one form of artificial intelligence that optimizes the fabrication process. AI analyzes tool wear and production data, adjusting parameters to hit certain thresholds as well as pinpointing defective components before they are created. These smart approaches to manufacturing efficiency greatly reduce scrap.

Engineers are able to develop advanced simulation software that virtually prototypes fabrication processes. Stamping operations can be simulated to predict material flow, thinning, and the formation of some defects before physically cutting the dies. This process reduces development time and cost while also improving production quality.

Flexible manufacturing systems are also available for fast adaptation to part and design shifts. With configurable tooling, universal fixtures, and advanced robot programming, fabrication lines can swap components in minutes as opposed to the traditional hours. This provides the capability to manage smaller production runs.

Frequently Asked Questions About Sheet Metal Fabrication in Automobiles

What makes sheet metal fabrication the preferred method for automotive body panels?

Sheet metal fabrication efficiently creates large, complex shapes with excellent surface quality and structural properties. The process handles the compound curves and precise dimensions body panels require while supporting high-volume production. Alternative methods like casting or molding cannot economically produce panels with automotive requirements for size, strength, and finish quality.

How thick is the sheet metal used in different parts of a vehicle?

Thickness varies widely based on component function and material. Exterior body panels typically use 0.6 to 1.0 millimeter steel or aluminum. Structural components might use 1.5 to 3.0 millimeters. Frame members in trucks can exceed 5 millimeters. Thinner gauges reduce weight while thicker materials provide strength where needed.

Can damaged automotive sheet metal components be repaired or must they be replaced?

Minor damage to non-structural panels can often be repaired through techniques like paintless dent removal or traditional bodywork. Structural components with damage affecting integrity typically require replacement to ensure crash protection. Modern adhesive bonding and welding in some vehicles makes panel replacement more complex than older bolt-on designs.

Why are some vehicles switching from steel to aluminum sheet metal?

Aluminum offers significant weight savings, with panels weighing 30-50% less than equivalent steel components. This improves fuel efficiency, acceleration, and handling. Electric vehicles particularly benefit from weight reduction as it extends battery range. However, aluminum costs more and requires different fabrication equipment and techniques.

How do manufacturers ensure sheet metal parts fit together properly?

Dimensional control throughout fabrication processes ensures components meet design specifications. Fixtures and gauges check parts during production. Body assembly uses precise jigging and robotic positioning to maintain tolerances. Modern measurement systems verify completed assemblies, providing feedback for process adjustments.

What skills do workers need for modern sheet metal fabrication careers?

CNC equipment operation requires understanding of machine programming, tooling selection, and quality control methods. Operators need mechanical aptitude, attention to detail, and problem-solving abilities. Technical training programs teach fabrication principles, safety procedures, and equipment operation. Advanced positions require engineering knowledge of materials, forming processes, and manufacturing systems.

Building Understanding of Automotive Sheet Metal Fabrication

Learning how sheet metal is made and how it is used in cars made by CNC machines is really important for understanding the basics of manufacturing. Sheet metal is used in the making of cars which is really versatile technology and focuses on beauty and strength. Importantly, it does all of this efficiently.

With the automation and new materials introduced in the automotive technology, sheet metal fabrication has been adjusting in all different ways. While the techniques and materials used change, the most important elements of changing flat sheets into complex 3D shapes, will mostly stay the same.

Understanding sheet metal scale will big help you have a deep understanding of the construction of a car, no matter which client path you are taking in automotive engineering, the manufacturing industry, or for the pure curiosity of it all. Sheet metal fabrication provides endless new ways to design and build new cars, and that is why it is important and it has so much potential for new ways to change and build inventions.

Comments